India Origin Trip

Recently I was fortunate to be in a position to travel to India on behalf of Bennetts and visit some plantations that we purchase our coffees from as well as the dry mill that processes these coffees.

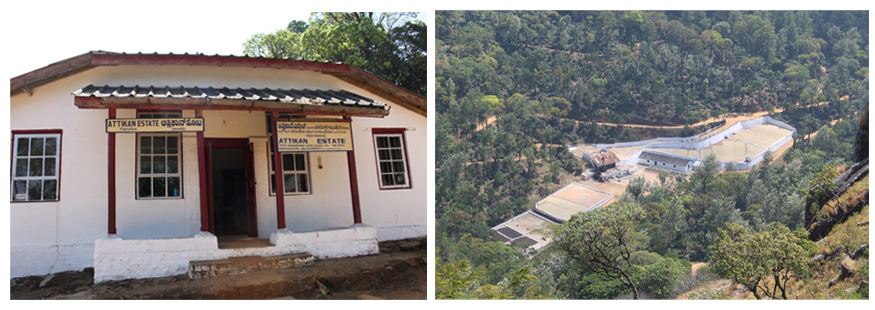

The first Estate that I visited was Attikhan Estate which is

120 km south of Mysore in the Chamraj Nagar District within the Biligiri Rangan

Hills. This Estate has east and west facing slopes with a unique topography,

natural source of water and is a natural habitat for wild animals such as elephants,

tigers, leopards, black bear, wild gaur, spotted deer and monkeys.

Attikhan Estate has 338 acres of Arabica (SLN 795, SLN 9 and Catimor) trees planted at an elevation of between 1375 - 1650 meters above sea level. Temperature averages between 12° C in winter and 28° C during summer with an average of 60 to 70 mm of annual rainfall.

Attikhan Estate was first established in 1882 by Scott Randolf Morris who arrived on horseback from Coonur. The tomb of his horse “Akbar” is still next to the Estate bungalow today. After he was wounded by a Bison his wife managed the Estate. The Estate was passed on to their son A. E. C. Morris.

The second Estate I visited was Kondadkhan Estate which is located 65 km from Chikmagalur in the Western Ghats adjacent to the Bababudangiri Hills and Muthodi Reserve Forest. Its elevation is on average 1056 metres above sea level with an area of 398 acres of which 60 acres is Robusta (Old Robusta and SLN 274). Arabica varietals grown are SLN 795, SLN 9 and Catimor.

The Estate is quite hilly and sits in a beautiful natural forest with most of the area facing east. Rainfall is between 65 to 85 mm per annum and temperature ranges between 16°C in winter and 32°C in summer.

Kondadkhan Estate was established by W. L. and C. S. Crawford (two brothers from Britain) in 1890.

Staying overnight on the Estate was exciting and a thoroughly enjoyable experience.

Kalledevarapura was the third Estate I visited. It is a 125 acre plantation which was established in the early 1900s in the Bababudangiri region, about 250 km from Bangalore. Its annual production of Arabica SLN 795 is approximately 75 MT.

The Estate is eco conscious and uses a perennial waterfall to generate electricity, the organic matter that is derived from the solid waste (skin and mucilage) from the pulping station is used for fertilizer.

Coffees from all the Estates are grown under native trees such as Silver Oak and Fig for filter shading, which along with the minimal use of chemicals contribute in preserving the purity of the environment as well as enhancing unique flavour profiles. The coffee trees are segregated in different blocks all of which have unique stains and flavour profiles. The crops are interspersed with pepper, areca nut, Jackfruit and oranges.

The coffees are harvested with three rounds of selective hand picking and are processed via pulpers with natural fermentation and slow drying on racks and patios in the drying yard. Large vats keep each block or strain separate.

Free accommodation, water, education and health care is afforded to employees and their families. There are crèches for infants and subsidised milk is available from the cattle on the Estates. Residents of neighbouring estates and villages can also access free medical treatment.

There are well equipped hospitals on site with resident doctors and nurses. Serious medical problems are given specialised treatment at the Estate’s cost.

After visiting the plantations I visited Allanasons dry mill in Hassan. The tour of their operations was impressive! Trucks were in a queue down the road waiting to unload the parchment. Samples are taken from the bags at the top of each truck that arrives and are quickly hulled and assessed for quality. If the first samples are acceptable then the truck is fully unloaded and fresh samples are taken from every bag, then hulled and assessed again. Only on final acceptance of quality the truck can leave.

Inside the factory the coffees are hulled and polished before computer controlled triple sorting and grading takes place. The coffees then go through a final hand sorting of which one 60kg bag can take up to a day to sort through.

After touring the mill I went to their cupping lab to select new crop coffees including our new Tiger Mountain. Allanasons cupping lab has two sample roasters, an Agtron colour scanner, a single group La Marzocco espresso machine and a commercial grinder.

After tasting these special coffees on the Estates and at Allanasons lab I am looking forward to them arriving in Australia soon. We will keep you posted as they are close to arrival.